Bioethanol Production and Applicability

Nikolett Pézsa

Department of Automobiles, Budapest University of Technology anad Economics

HUNGARY

Szabolcs Szemerey

Első Honi Biogáz Kft., HUNGARY

Rising CO2 emission levels, energy dependency and oil dependency also affect the transport sector. The application of alternative fuels offers one way to tackle global challenges. Among alternative fuels the application of biofuels has caused worldwide concern. The evaluation of biofuels depends on a lot of factors, such as applied production technology, feedstock and location. However, the debate on food versus energy production still remains, first generation biofuels are competitive in some regions of the world. With the application of second generation biofuels most of the problems concerning biofuels are expected to be overcome. However, second generation biofuels are unlikely to become commercial before 2015.

The aim of this paper is to give an overview of the current status of biofuels worldwide and to introduce the situation and future possibilities in Hungary.

1 Introduction

Global problems such as CO2 emission, energy dependency and oil dependency urge for solutions in all affected sectors and therefore also in the transport sector. The biggest challenge for the transport sector is that CO2 emissions energy dependency and oil dependency have to be reduced at the same time when increased mobility needs have to be met. The increase of energy efficiency and the application of alternative fuels are alternatives to tackle global problems in the transport sector. [1]

Several countries have introduced policies for encouraging the production and use of biofuels, including the United States, where the Energy Independence and Security Act 2007 mandates a significant increase in both first- and second generation biofuels use by 2020. China has a target to 2020 and the European Union has a target for biofuels to meet 10% of road transport demand by 2020. [2]

Australia, New Zealand, Colombia, South Africa, Thailand, Japan, Indonesia, Mexico and Canada also have mandates for ethanol blends. [2]

2 Global status of biofuels

Projections concerning future biofuel output are very sensitive to assumptions.

.jpg)

The IEA’s World Energy Outlook 2008 Reference Scenario projects the world biofuels output to meet 5% of road-transport fuel demand by 2030 (Figure 1), while in the WEO Alternative Scenario output reaches 7% of road-fuel use in 2030. The IEA’s Energy Technology Perspectives (2006) suggests bioethanol and biodiesel could meet some 13% of global transport fuel demand and contribute some 6% of global emission reductions by 2050. [2]

The world’s largest producers of bioethanol are Brazil and the United States. As it can be se.jpg) en in Figure 2, compared to the Brazil and the United States., the European Union’s fuel alcohol sector is rather small.

en in Figure 2, compared to the Brazil and the United States., the European Union’s fuel alcohol sector is rather small.

Nowadays the United States produces every month more than the EU produces in a year. The biggest EU producers of ethanol are France, Germany, Spain, Poland followed by Sweden and the UK. [3]

3 Bioethanol production

The conventional production of bioethanol is based on the conversion of 6-carbon sugars to ethanol by fermentation. If the sugar content is present in forms of polymers than the sugar content of the polymer must be released, which is mostly done with the application of enzymes. The production process is finished with the distillation step, where ethanol is distilled to fuel grade. In practise this process is used to produce ethanol from starchy biomass. A wide range of available feedstocks exist for conventional ethanol production: cereal crops, corn (maize), sugar cane, sugar beet, potatoes, sorghum, cassava. [4]

The world’s largest producers of bioethanol are Brazil and the United States. In Brazil bioethanol production is based on sugar cane, while in the United States it is based on corn.

While conventional bioethanol production only uses sugar and starch components, advanced bioethanol production processes may utilize all available cellulosic materials, such as energy crops, agricultural residues (straw, corn stover), waste streams (MSW, food waste) and forestry resources. [4]

Lignocellulosic feedstocks are heterogeneous both in structure and chemical composition. This heterogeneity has a strong influence on the production process design. [5]

Ethanol production of lignocellulosic feedstocks composes of pretreatment, hydrolysis, fermentation, separation and distillations steps. The role of pretreatment to release the cellulose and hemicellulose become more relevant. In some feedstocks 5-carbon sugars might also be present. [4]

The possible presence of 5 carbon sugars influences the hydrolysis and fermentation steps, since appropriate enzymes have to be chosen to hydrolyse the 5 carbon sugar containing polymers and in the fermentation step appropriate microorganisms have to be selected, which are capable of the co-fermentation of both 6 and 5 carbon sugars. [5]

4 Energy requirement and emissions

Fossil energy input and emission levels from biofuel production depend on a lot of factors, such as the applied process, the feedstock and local conditions. In Brazil the production of bioethanol from sugar cane is energy efficient, due to the fact that sugar can be easily extracted and crop yield per hectare is high. If bagasse is used for providing heat and power to the process than the fossil energy input required for each ethanol energy unit can be very low. This results in a low well-to-wheel CO2 emission, 0.2-0.3 kg CO2/litre ethanol. Compared to 2.8 kg CO2/litre for conventional gasoline this means a 90% reduction. In the case of sugar beet more energy input is needed and therefore only 50-60% emission reduction can be reached compared to gasoline. [4]

Ethanol production based on cereal and corn feedstock can be even more energy intensive, since fossil energy input can reach 60-80 % of the energy contained in the final fuel. As a result CO2 reductions compared to gasoline are around 15-20 %. [4]

CO2 emission reductions from ligno-cellulosic feedstock can be 70% compared to gasoline and there is a further possibility of improvement with the application of electricity cogeneration.

5 Production costs

Ethanol energy content by volume is two-thirds that of gasoline, so in the literature costs mostly refer to litre of gasoline equivalent (lge)

Main factors contributing to the cost of biofuels are feedstock types, applied production processes, labour costs, credit for by-products, agricultural subsidies, food and oil markets.

In Brazil ethano.jpg) l made from sugar cane ($0.30/lge) is cost competitive with gasoline ($0.3-$0.4/lge). However in other regions, costs can be more than $0.40-$0.50/lge.

l made from sugar cane ($0.30/lge) is cost competitive with gasoline ($0.3-$0.4/lge). However in other regions, costs can be more than $0.40-$0.50/lge.

Ethanol made from maize, sugar beet and wheat costs $0.6-$0.8/lge, with a potential to be reduced to $0.4-$0.6/lge.Ethanol made from ligno-cellulosic feedstock cost around $1.0/lge at the pilot scale. The costs of ligno-cellulosic ethanol are projected to decrease in the future, due to process improvement, the application of low-cost waste feedstock and co-production of other by-products. Figure 3 shows possible biofuel cost ranges in the future. [4]

6 Concerns regarding biofuels

The application of first generation bioethanol has raised worldwide concern. The food versus fuel production debate still remains an issue. First generation biofuels are accused to rise food prices due to competition with food crops. They are considered to be an expensive option for energy security and they can only provide limited GHG reduction benefits. An effect on accelerating deforestation and a negative impact on biodiversity are also often mentioned drawbacks. [6]

It must be mentioned though that not all drawbacks refer to every type of first generation biofuels, since the evaluation of biofuels depends on a lot of factors.

Most of the problems associated with the first generation biofuels could be overcome with the application of second generation biofuels.

However second generation biofuels are relative immature and projections for second generation fuels to become commercial are wide ranging but considered to be unlikely to occur before 2015. As it can be seen in Figure until 2007 second generation biofuels have remained around 0.1 % of total bioethanol production. [6]

7 Second generation demonstration plants

Integrated research programmes deal with combining process development units with pilot or demonstration-scale facilities around the world.

.jpg)

Main operating process development units are at University of British Columbia, at Lund University (Sweden), at RISO/DTU (Denmark) and at the US National Renewable Energy Lab. Pilot facilities can be found in Sweden (Etek Etanolteknik), in Spain and the USA (Abengoa) and in Canada (Iogen). [6]

8 Application in vehicles

Ethanol has a high octane number and therefore it is unlikely to cause knocking in spark ignition engines. 5-10% ethanol blends can be used in conventional spark ignition engines without significant technical changes. In more complex engines with injector alcohol can damage the high precision injection unit. This might also happen to the intake valve and to the valve seat. New flex-fuel vehicles can run on up to 85% ethanol blends. New flex-fuel vehicles are mainly running in Brazil, in the United States and in Sweden. [4]

9 Status in Hungary

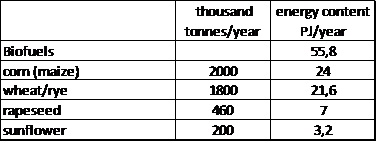

Table 1 gives an overview of the current Hungarian biofuel potential. Possible feedstocks for for bioethanol production are primarily maize and wheat. To a smaller extent other sugar and starch containing plants, such as sugar beet, potato and artichoke can also be taken into account. [7]

The wide spread use of ligno-cellulosic second generation biofuels is only expected by 2012-2015. Among industrial waste streams paper sludge could be an alternative feedstock for bioethanol production. 50000 tonnes of paper sludge are produced yearly in Hungary. [8]

The Hungarian ethanol produ ction capacity is 210 million litres/year in 2 factories. The US based ethanol giant Fagen is going to construct a bioethanol factory (capacity 200 million litres) in Hungary based only on corn. As a member of the Europen Union the target set by the Directive 2003/30/EC also applies to Hungary. According to the directive fuels should contain 5.75% biocomponents. [9]

ction capacity is 210 million litres/year in 2 factories. The US based ethanol giant Fagen is going to construct a bioethanol factory (capacity 200 million litres) in Hungary based only on corn. As a member of the Europen Union the target set by the Directive 2003/30/EC also applies to Hungary. According to the directive fuels should contain 5.75% biocomponents. [9]

10 Conclusion

Global problems such as CO2 emission, energy dependency and oil dependency urge for solutions in the transport sector. One way to mitigate the global problems is the application of biofuels. First generation biofuels caused concerns worldwide. Most of the problems of first generation biofuels are expected to be overcome when second generation biofuels will be commercially available. However, this is unlikely before 2015. The evaluation of biofuels is difficult and no general rules can be applied, since the evaluation depends on a lot of factors, such as location, production technology and feedstock. Main factors in the evaluation are energy balance and cost competitiveness. Although first generation biofuels have a lot of drawbacks, they are now commercially available and are also cost competitive with fossil fuels in some regions of the world. Projections for biofuel output are also very sensitive to assumptions, but the growing tendency for biofuels is common in all assumptions. More and more countries start to introduce aggressive policies for the promotion of biofuels. In Hungary the current bioethanol production capacity is 210 million litres/year. In the future a new factory is going to be built based on corn.

References

[1] K. Döhmel, Future Mobility from a Fuels Perspective, 29. Internationales Wiener Motorensymposium 2008, ISBN:978-3-18-363912-0

[2] World Energy Outlook 2008, http://www.worldenergyoutlook.org/ 2010-10-04

[3] http://www.ebio.org/policy.php 2010-10-03

[4] IEA Energy Technology Essentials, Biofuel Production OECD/IEA 2007 www.iea.org 2010-10-03

[5] K. Olofsson, M. Bertilsson, g. Lidén, A short review on SSF- an interesting process option for ethanol production from lignocellulosic feedstocks Biotechnology for Biofuels, http://www.biotechnologyforbiofuels.com/content/1/1/7

[6] From 1st to 2nd generation Biofuel Technologies, http://www.iea.org/papers/2008/2nd_Biofuel_Gen.pdf 2010-10-03

[7] Magyarország 2020-as megújuló energiahasznosítási kötelezttségvállalásának teljesítési ütemterv javaslata, Műszaki-gadaságossági megújuló energiaforrás potenciál vizsgálata a célkitűzés teljesítésére vonatkozó NCST bontása szerinti forgatókönyvek. http://etanol.info.hu/oldal/Szakmai_anyagok, 2010-09-14

[8] Zs, Kádár, Zs. Szengyel, K. Réczey, Simultaneous saccharification and fermentation (SSF) of industral wastes for the production of ethanol, Industrial Crops and Products 20, 2004, 103-110

[9] DIRECTIVE 2003/30/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCILof 8 May 2003on the promotion of the use of biofuels or other renewable fuels for transport http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32003L0030:EN:NOT 2010-09-14

Author data

First Author: Department of Automobiles, Faculty of Transportation Engineering, Budapest University of Technology and Economics. 1111 Budapest Stoczek street. 6. J bld., Hungary. E-mail: pezsa.nikolett@auto.bme.hu

Second Author: Első Honi Biogáz Kft, 6000 Kecskemét Vízmű street 9, Hungary. E-mail: szemerey@ehbkft.eu

Ajánló

Autótechnika

- A JÖVÕ MOBILITÁSA ELÕADÁSSOROZAT

- Suttogó fékbetétek: Akusztikai tesztek a fokozott fékezési

- VÁSÁRIDÕ